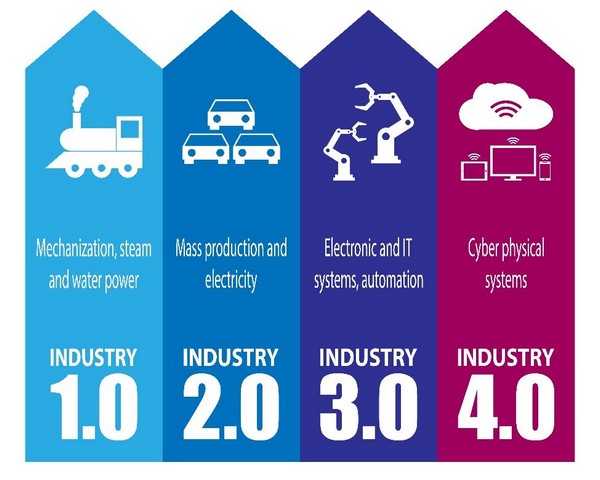

Industry 4.0 refers to the fourth industrial revolution in history, which occurred in the early 2010’s (the first took place in the 18th century, the second in the early 20th century, and the third in the 1970’s). It can be succinctly defined as the convergence between new digital technologies and physical means of production.

In order to offer the most advanced solutions to the steel fabrication sector, Industry 4.0 is at the heart of our development strategy.

You will find in this page a list of the main concepts that define it and how we respond to them.

Our first goal is to convert drawings into CNC programs to drive machines automatically. After configuring the workflows in our software, we can also create programs to route pieces automatically in the workshop.

We provide our solutions on many different devices to improve flexibility and effectiveness: computers, tablets, smartphones, scanning systems, etc. All of them are connected to a central network infrastructure.

Our solutions allow to put together capabilities of the workshop and actual operations required on pieces. Then, we can route them intelligently and make sure they are produced in the most efficient way. We also check production before it begins by using integrated emulators.

Our solutions allow to share information live and efficiently. We collect data from both CNC machines and manual workstations and share them instantly as needed. Then, pieces and machines statuses can be followed live by all the employees. Productivity can also be analyzed instantly.

Whether it is the projects imported in our software, the machines’ capabilities or the production feedback collected from the workshop, we have to deal with a lot of information. We can use these data accurately to prepare, optimize, track and analyze production.

We understand that of the key for our customers is to manage the flow of information between all their systems. That is why we have developed the standard format PNI to exchange data with MIS and ERP. In addition, we have developed BIM interfaces with CAD software to facilitate production thanks to all the information created by the detailing office.

To manage the massive flow of information exchanged between all the systems within companies, we provide a cloud-based storage. Then, we secure and optimize the management of data.

By bringing new technologies to steel fabrication, we contribute to boosting the sector and make it attractive to the young generation. Plus, by increasing information sharing within companies, we help employees feel much more involved in projects. Finally, by improving the productivity of the steel industry, we support the sustainability of this material in construction, known for its ecological properties.