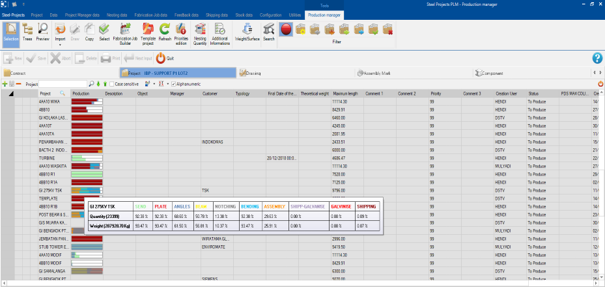

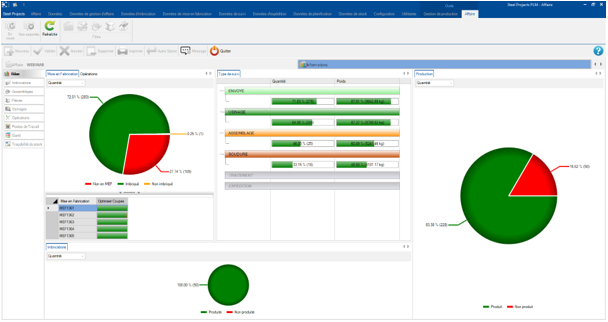

Thanks to the automatic feedbacks collected from the CNC machines and the manual feedbacks collected from manual workstations, you can follow the progress of your production in real time with just one click. You can also follow the activity of your workshop in real time.

A color codes is applied to each desired step of production.

Those colors can be seen directly in the 3D model in Steel Projects PLM to track production on the desired level (BIM 4D).

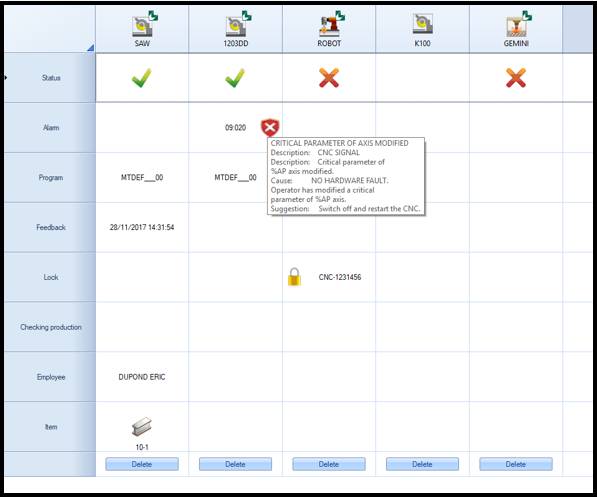

At each desired workstation (automatic or manual), see some live information such as:

A mobile version of the Workshop monitoring is available. It allows even more reactivity as the potential alerts can be sent directly on smartphone to employees in the workshop.

The messaging system allows to send information back to the office in order to know what is happening in the workshop and then be more reactive in decision making.

1

Improved control of workshop activity

2

Maximization of machine capacities

3

Time saving (reduction of unnecessary trips in the workshop)

4

Flexibility

5

Simplification of processes

6

Reduction of bottlenecks

7

Productivity gains

8

Improvement of your customers’ satisfaction

Need a demo?

Make an appointment with one of our experts to discover how Steel Project PLM will help you better manage your production.