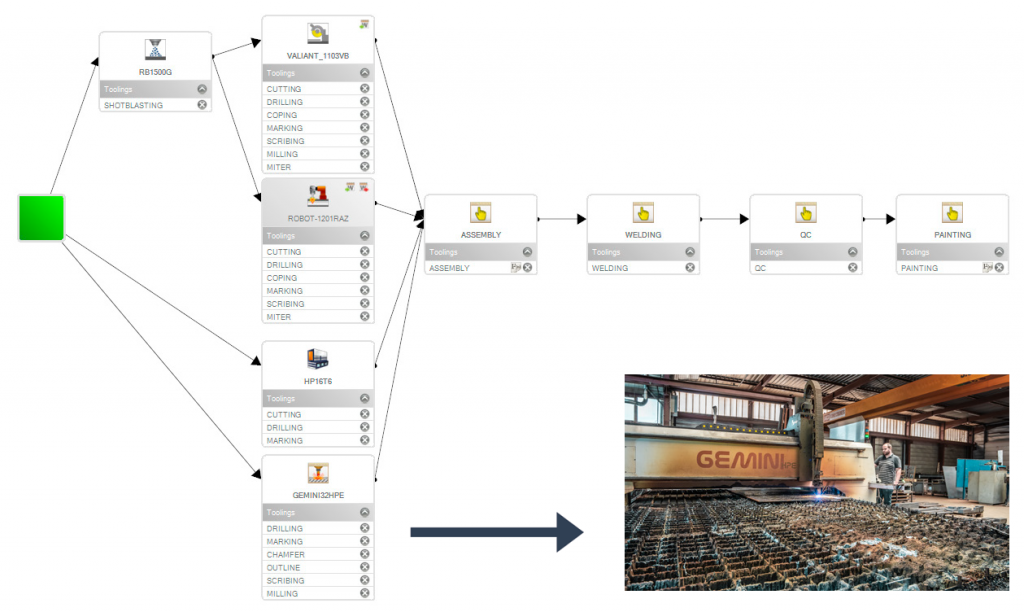

Our steel fabrication production manager module allows you to start fabrication in the most optimal way and is one of Steel Projects PLM’s strongest added values.

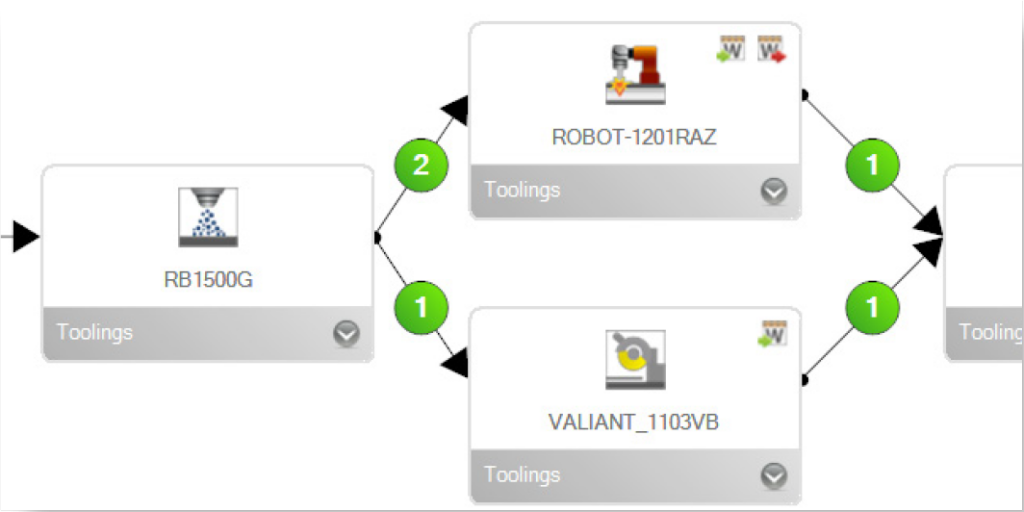

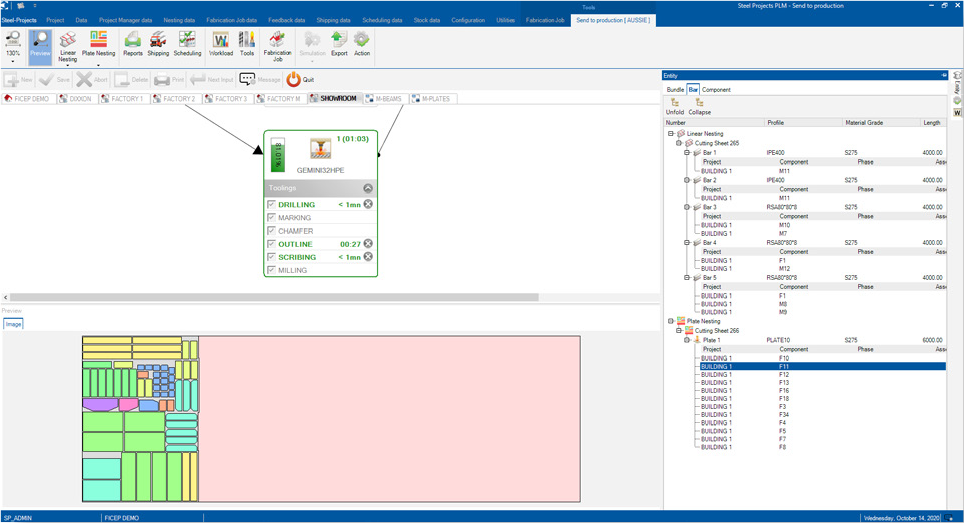

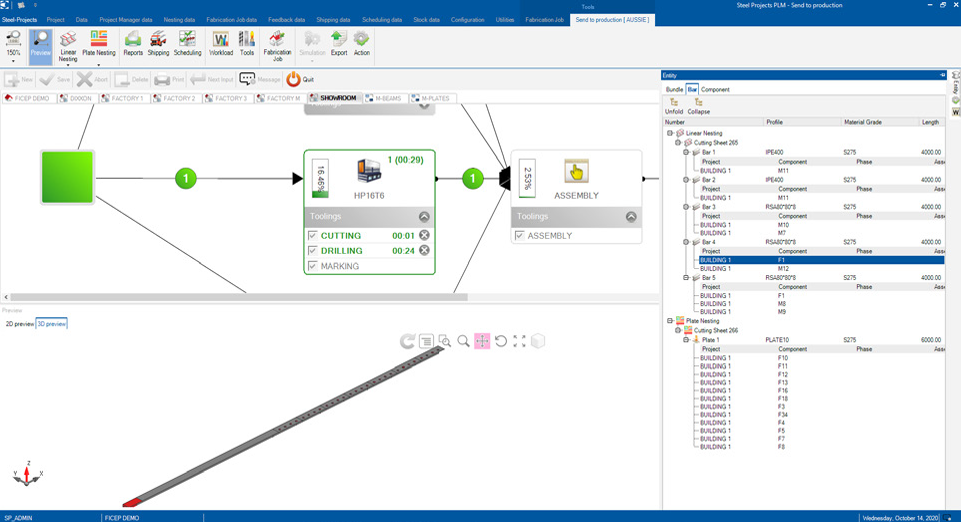

Organize your production with the creation of fabrication job that you will be able to track through production. Filters can be used to create groups of pieces that you want to include in them, depending on different factors (type of profile, thickness, etc.). You can mix pieces from different projects.

Forecasted production times can be calculated according to predefined formulas. Those are available by part, group of parts, nesting, or fabrication jobs, and by workstations and more precisely by specific operations.

The scheduling feature allows you to assign jobs on a GANTT chart to help you schedule your production and anticipate the resources needed to manufacture your projects.

Once production is prepared, all files can be exported to the desired workstations. CNC data for CNC machines, work order for manual workstations.

It is possible to configure several sites and their associated virtual workshop and workflows and manage them from one. Jobs can also be exported to those external sites.

1

Time saving and optimization of resources

2

Flexibility

3

Reduction of bottlenecks

4

Maximization of the workshop’s capacities

5

Simplification of processes

6

Productivity gains

7

Reduction of unnecessary handling operations

Need a demo?

Make an appointment with one of our experts to discover how Steel Project PLM will help you better manage your production.