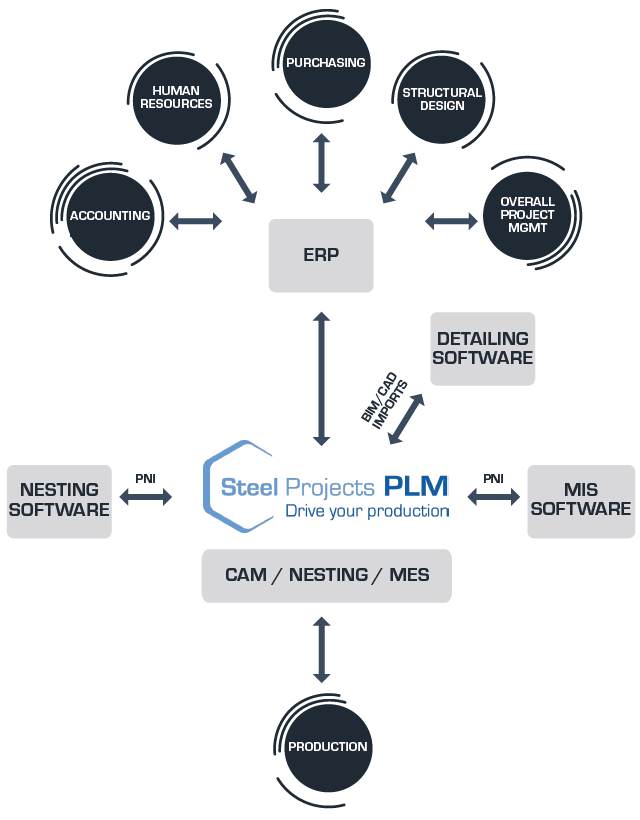

Nowadays, digital continuity is a key success factor for any company. Indeed, even if the ERP often plays a central role in the company, it requires good communication with other systems in the company throughout the value chain to optimize all stages of the process. These other systems can be production management software such as Steel Projects PLM, but also plate nesting software or industry-specific information systems (MIS). Steel Projects PLM includes interfaces to communicate with other systems.

Steel Projects PLM is at the heart of the production process and allows the easy exchange of various types of data with external systems thanks to the standardized PNI format that we have developed, or through specific developments carried out at the request of our customers.

This format was developed by Steel Projects and its specifications were given to other players on the market if they wanted to comply with them to exchange data easily with Steel Projects PLM. It allows to import fabrication jobs, nesting, stock information, etc.

Some of our partners such as Tekla PowerFab, Strumis, Fabtrol, Construsteel, Lantek or Sigmanest have already included the possibility to exchange PNI files within their software.

Some specific developments can be required on particular cases and our development team can then customize special interfaces on demand. This already happened with some bug player in the ERP industry for example. These are subject to specific quotations depending on the amount of work required.

The following diagram summarizes the different exchanges that can take place between Steel Projects PLM and external systems throughout the process, along with their associated formats:

The goal for our customers is to achieve complete digital continuity, essential to maximize their processes and thus obtain significant productivity gains. Finally, it allows them to take full advantage of each software and its possibilities.

1

Saving of time

2

Simplification of processes

3

Flexibility

4

Error reduction

5

Reduction of paper use

Need a demo?

Make an appointment with one of our experts to discover how Steel Project PLM will help you better manage your production.